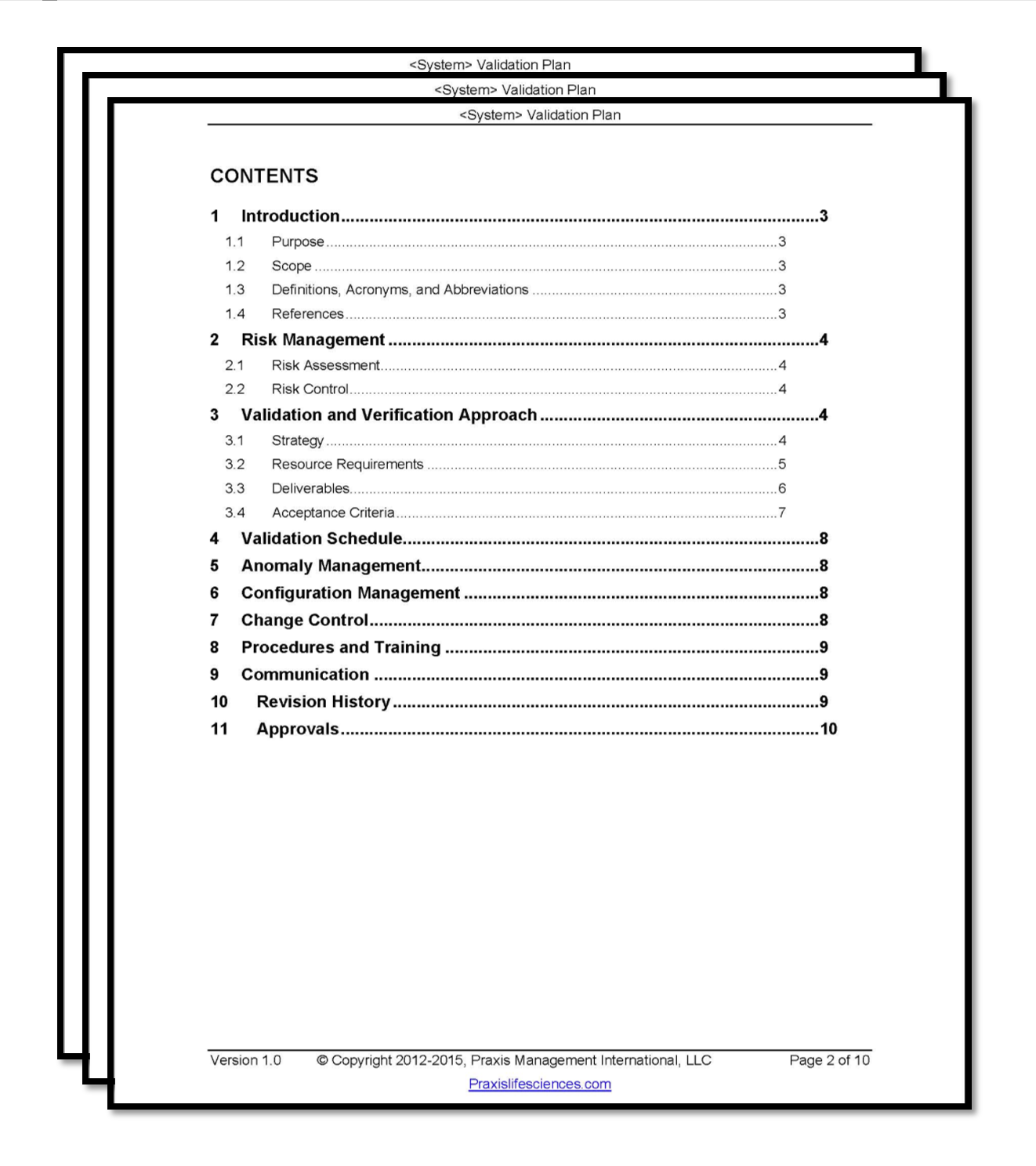

Table Of Content

When such a scenario emerges, the product shall have met the requirements of the designer but fail to achieve what the end user or customer wants. As one of the leading online platforms in the medical device sector, 4EasyReg offers extensive support for regulatory compliance. At this stage, your manufacturing team doesn't involve any changes to the production design or production molds. During this stage, your engineering team will realize potential hardware defects and blend earlier prototype versions to create one that looks and performs something close to the product designer’s vision.

Tree testing

During these tests, the team performs risk management protocols to identify any weak points in your product, fix them, and test the product again. The objective of performing this final test is to verify mass production of the product and create sellable products. The PVT stage optimizes and stabilizes the production and assembly line's speed, operation, and daily yield. Its success depends on the availability of all components, materials, and processes required in mass production. Your team determines that the final product meets the desired design and functionality requirements at the end of this stage. With concept testing, you ask real users or potential users to respond to early product design ideas and hypotheses, usually presented as drawings, paper prototypes, or presentations.

Information & Training. Product & Process Validation.

In some industries this is referred to as a First Article Inspection (FAI), a first off, or Production Part Approval Process (PPAP). Depending on customer requirements this can be recorded as a standalone document, or an addition to the Statement of Compliance created in the verification step. Another example of verification is accessibility testing, which you can do both internally and externally. When used in tandem, both are essential for ensuring product quality and user satisfaction. The sooner you begin thinking about how you’ll verify these design inputs, the smoother the actual verification process will go. In fact, you should be considering how you’ll verify your design inputs while you’re defining them.

Digitizing Your Business Growth

After successful testing, this group provides approval or feature changes required to move into subsequent development stages. These prototypes may also act as demonstration units in the team's first sales meetings. An engineering validation test, EVT, is a prototype production that mimics final design functionality.

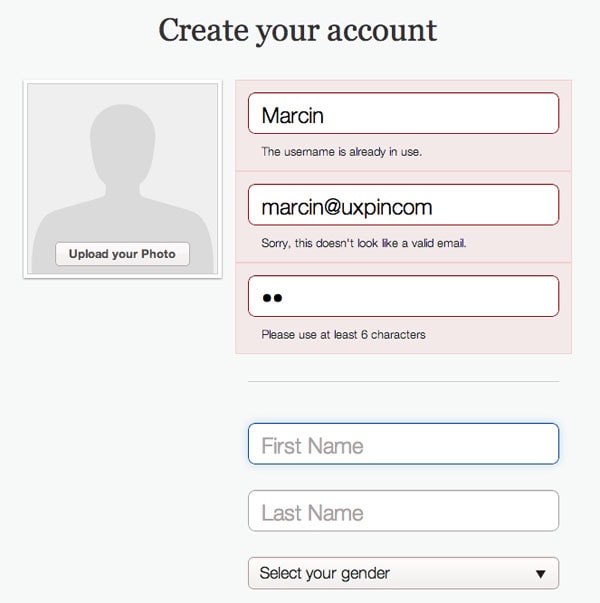

You can start thinking about how you’ll verify your design inputs as soon as you’ve defined them, and you may even be able to develop some of the tests you’ll use during product development. Usability testing is probably the most common and arguably the most potent design validation method. Firstly, this design validation method involves interviewing actual users or potential users, which is the most reliable source of information. Secondly, usability testing usually involves creating interview scripts that allow you to compare answers to the same sets of questions. The downside though is that usability testing is time-consuming and relatively not cheap. Gathering data from users can help designers validate assumptions to make informed decisions.

Explore AI Writing Tools: A Quick Guide

You’ll be able to easily navigate between test reports and protocols to your design control verifications and validations, while also seeing related design inputs, risk controls, and components. Let’s learn more about the difference between design verification and validation, discover mistakes to avoid, and the benefits of both processes. These two critical steps ensure a product is functional and meet user needs.

What are design verification best practices?

It’s also a good idea to test with different user groups and demographics. Some testing and product insights tools offer filters you can use to see results for particular kinds of end-users. With Hotjar, for instance, you can sort recordings to evaluate users in a particular region or those who had a positive or negative experience. Usability task analysis testing checks whether users can complete key tasks on your product or website without hitches. It typically involves instructing a group of participants to complete specific actions—for example, an ecommerce app might ask users to find a product, add it to their cart, and check out.

While they’re both part of the design process, they have different focuses. Design validation and verification are essential components of successful device development. With shared understanding among the team, as well as the right tools, you have solid framework for getting your device to market. Detailed reports include configuration management and release reports, test results by testing type or product version, and issues found during the verification activity. A design verification traceability report shows test results and coverage for the requirements. Finally, reviews are completed and approved after each design verification activity.

The differences between design validation and verification

This is the stage where you actually build a version of the product and validate against the user requirements. Always keep in mind that testing your designs is an iterative approach so instead of treating it like a one-off project, incorporate it in your design thinking process. Design validation plays a critical role in aligning the design with the needs of the users and the business. This can in turn lead to the creation of seamless and meaningful experiences that help businesses achieve their strategic goals. Make sure to involve your stakeholders and share any findings to foster the product and business alignment.

The verification activities should cover all relevant aspects of the device’s design, including its components, software, packaging, labeling, and instructions for use. Manufacturers must ensure that the design verification is thorough, well-documented, and performed by qualified personnel. Greenlight Guru’s QMS solution features a dedicated Design Control Software workflow built specifically for medical devices. We understand the challenges of the design and development process, which is why with our software you can create detailed design control objects, link complex configurations, and attach documents with one click. Each of these steps is important in the design process because they serve two distinct functions. Together, they ensure that the product designed will satisfy the customer needs, and the needs of the customer are one of the key focuses for ISO 9001 and improving Customer Satisfaction.

It provides V&V targeted data capture and reporting to make production of reports simple and repeatable. Every impactful design decision needs to be validated by testing it on real users. In usability testing, the product or part of it is subjected to real-world scenarios and conditions to observe how it behaves. There are different approaches and techniques for assessing and confirming that a design matches the product specifications and requirements.

Keysight EDA 2024 Integrated Software Tools Shift Left Design Cycles to Increase Engineering Productivity - Yahoo Finance

Keysight EDA 2024 Integrated Software Tools Shift Left Design Cycles to Increase Engineering Productivity.

Posted: Tue, 26 Sep 2023 07:00:00 GMT [source]

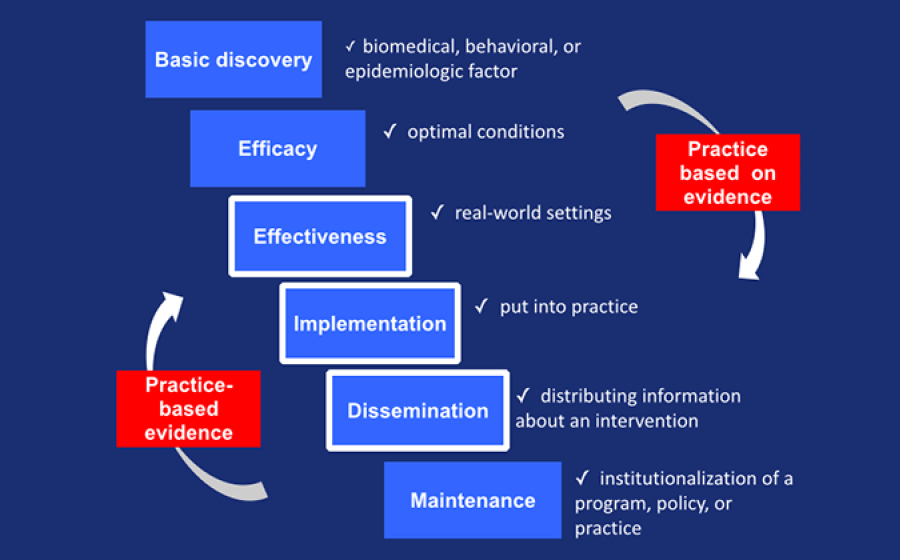

Design verification and validation are crucial processes in product development. They can lead to a high-quality product that meets user needs and positively impacts the market. These processes also save time and money, leaving resources for more innovation and potential revenue. It’s crucial to note that the specific details and steps of the design validation can vary depending on the product complexity, industry, and regulatory requirements. As such, the DVP design validation plan should be customised to meet the project’s specific requirements to ensure the validation is effective.

Depending on the industry in question, there are various DVP design validation plans used, including market studies, calculations, and product testing. Effective product design testing methods help you avoid this scenario. By running tests, you’ll reduce your assumptions and truly understand your users and their experiences. Great testing lets teams proactively identify issues and create products that exceed user expectations. The engineering validation test (EVT) stage is all about incorporating and optimizing the crucial functional scope required for the product. The engineering prototype is a minimum viable version of the final commercial product, that is designed for manufacturing (DFM).

This part of the process also includes writing, test driving, and approving the test cases that will be used for verification. For instance, the design specifications and drawings might show the following. Keep in mind that while it will involve testing, there are other acceptable verification activities.

No comments:

Post a Comment